How to ensure a safe press run by making the right choices

No matter if you mount a few cylinders on your label press or up to 100 wide web sleeves a day. The mounting always has an impact on the print result. When preparing your sleeves and plates for the mounting there are just a few key factors. If you get them right, it will save a lot of trouble later on. Here we will look on the preperation of the sleeve before mounting the tape.

Cleaning the sleeves or cylinders

In order to make a plate mounting tape stick to the surface you want to mount it on, the surface has to be clean. Clean means:

- no adhesive residues

- no liquid residues

- no ink residues

- no dust

The cleaning agent you want to use is Alcohol / Isopropanol. Or the same mixed with water 50/50. In case you insist on Ethylacetate because you are in a hurry, that’s OK. But keep in mind to let it dry out after cleaning for at least 5 min.

Why is that important? – Sleeves usually have many tiny little scratches on their surface. The solvents that are used for cleaning sit in those tiny grooves and need time to evaporate. If a tape is mounted too early before solvents had dried out, the air gets trapped under the tape. Bubbles start to appear after 30-60min and the press operator won’t like that, right?

So here is the step by step workflow:

- take the sleeve and clean it with solvent (or even better: clean sleeves right after press run and store them)

- let solvents dry for 5 min

- mount the tape by using a rubber blade or a pressure roller system in your plate mounter

[This machine has a white pressure roller system to press down the tape/plate.]

[This machine has a white pressure roller system to press down the tape/plate.]

Sleeves are then ready for the next step – Plate mounting. But before we get into that, we’ll take a deep look at the tapes. Their characteristics and how to chose them based on the print parameters. That area is too large to cover in one post so we will aproach it systematically be looking at:

- print design

- plates and sleeves

- substrates

Watch out for the next post on this topic and contact us if you want to get more info!

Supply issues with Cushion Mounting Materials?

Surge in demand? Shortage in supply? What is going on in the cushion backing for corrugated post print? Cushion mounting materials for corrugated flexographic post print increased the performance and printing quality significantly. Early materials to the market have...

What to do if the print design in post-print is larger than the maximum plate format?

Orders up to 2.8 m (110”) printing width have special requirements in prepress at Glatz Klischee and in printing at Hans Kolb Wellpappe. Written by Dieter Finna When corrugated cardboard packaging from the world's leading power tool manufacturer Stihl exceeds the...

Neuer Schaumunterbau für den Wellpappen-Direktdruck im Praxistest

Die vliesveredelte Rückseite erleichtert das Handling in der Druckmaschine Schaumunterbauten mit Vliesveredelung entsprechen dem neuesten Stand der Entwicklung in der Druckvorstufe des Wellpappen-Direktdrucks. Das Vlies auf der Rückseite erleichtert dem Drucker das...

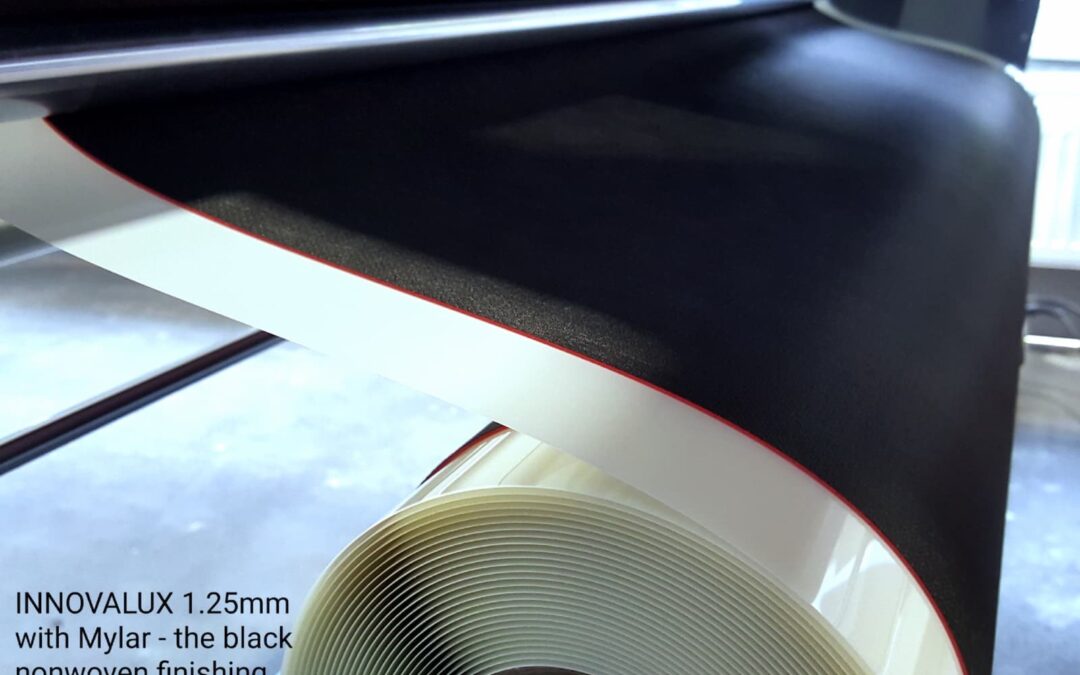

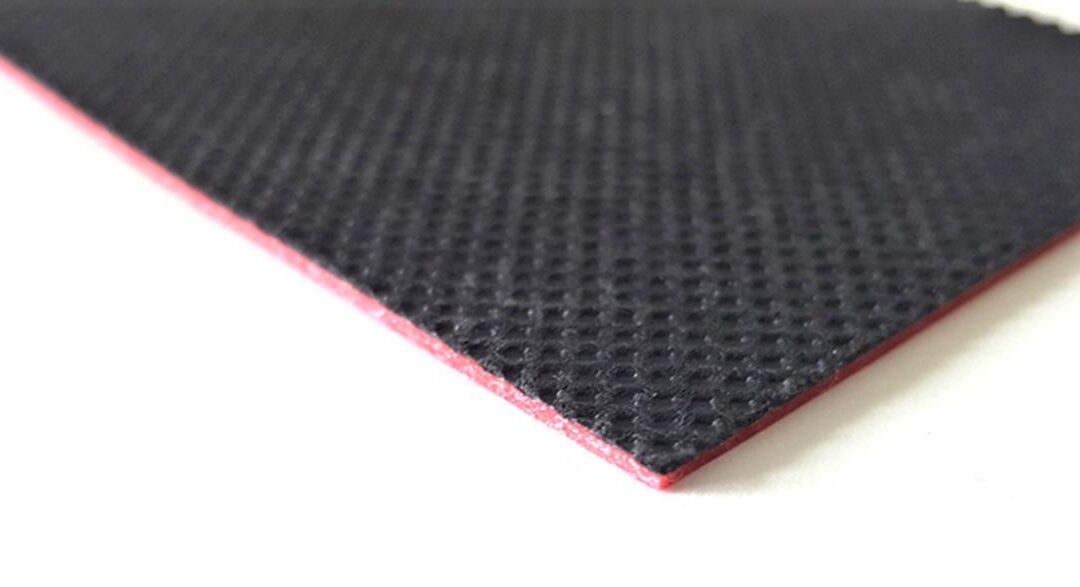

Flexo cushion backing foam: Nonwoven layer improves handling of flexo plates

Cushion backing foams Better handling of the printing plate in corrugated cardboard postprint Groundbreaking for the still young company Innova Flexo Products GmbH was the customer's request to further improve a proven product in corrugated post-printing. Based on...

INNOVA – Certified green shipments

INNOVA and sustainability activities For 90% of our domestic and 50% of our international shipments we choose climate neutral ways. By chosing partners who care about the environment and act responsibly.

INNOVALUX at #oneflexo

INNOVALUX at #oneflexo When it comes to mounting jobs with greater goals, INNOVALUX gives you that little extra in performance. This customer is using Kodak plates on a Flatmount machine. With INNOVALUX 1.7 prelaminated on 0.3mm Mylar nothing much can go wrong....